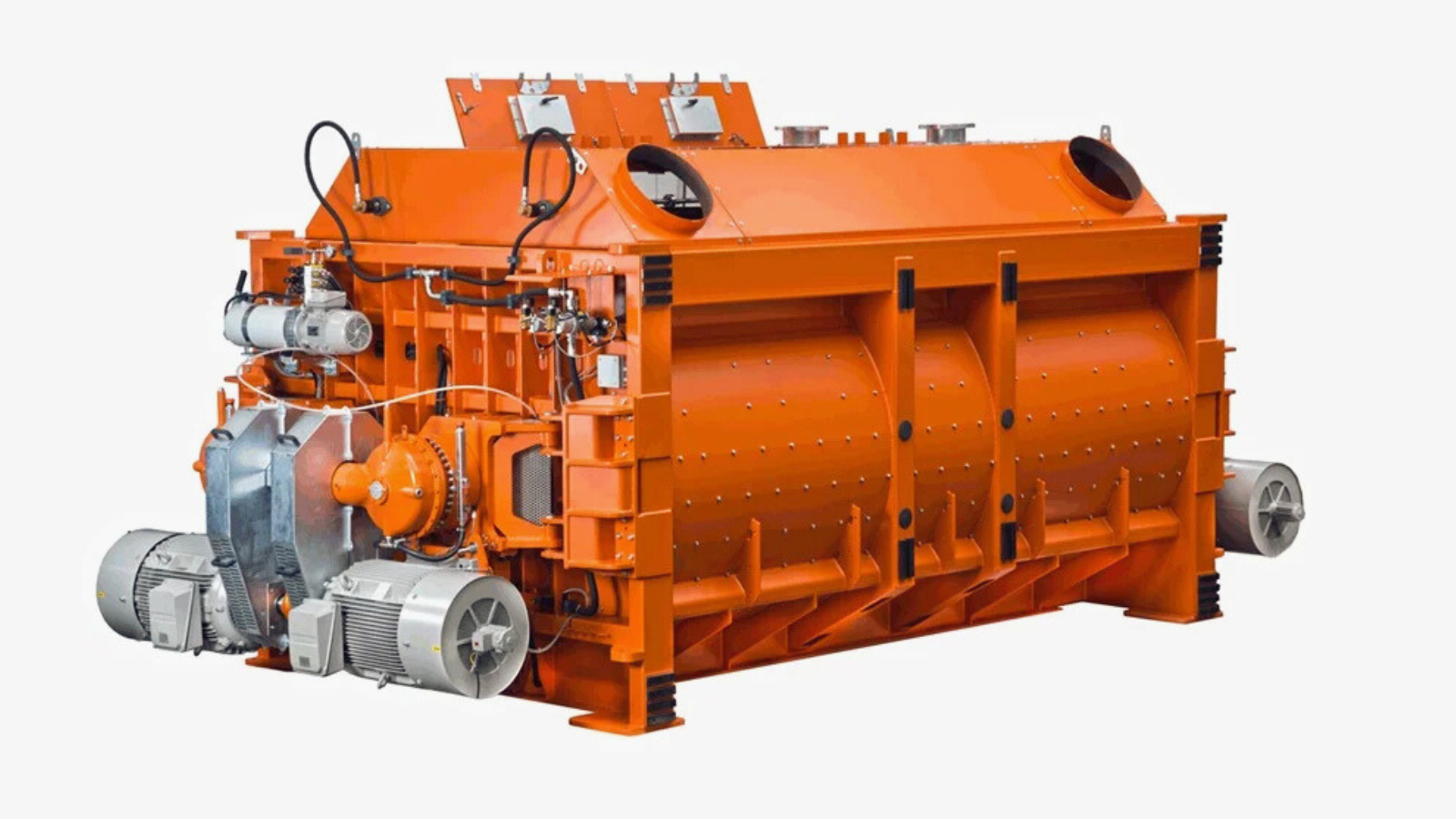

Compact Concrete Batching Plant

Gajjar Equipments Pvt. Ltd. is a well-known manufacturer, supplier, and exporter of Compact Concrete Batching Plants. We design our products keeping the requirements of clients in consideration. Our product is ideal construction equipment for manufacturing asphalt for building roads through batch mixing.

Home » Concrete Mixing Plant » Ready Mix Concrete Plants » Compact Concrete Batching Plant

- transport optimised

Compact Concrete Batching Plant

FAST & LOW-COST INSTALLATION

With the new GCP plant, GAJJAR offers a concept for a linear and transport-optimized concrete mixing plant. For use as a concrete filling station up to a powerful small plant in the ready-mixed concrete industry or for supplying concrete in the precast concrete industry.

All sub-assemblies (mixer platform, linear bins) are completely pre-installed and connected to enable fast installation. For assembly, the plant is unfolded and erected which reduces significantly the connection and installation costs.

FAST & LOW-COST INSTALLATION

- Easy to transport and install

- Option of no foundations, soil compaction of 250 kN/m² is sufficient

- Plug & Play – Plants electric and pneumatic components are completely pre-installed Short assembling times

- Expandable aggregate storage

Exceptional Concrete Mix Output

Capacity Range: 24 m3 to 90 m3

Advantages of Compact Concrete Batching Plant

- Space Efficiency: These plants are designed to occupy minimal space, making them ideal for projects with limited site area.

- Mobility: Many compact batching plants are mobile, allowing for easy relocation to different project sites. This flexibility is particularly useful for short-term projects or projects spread across multiple locations.

- Quick Installation and Setup: Compact plants are often designed for rapid assembly and disassembly, reducing downtime and allowing for faster project initiation.

- Cost-Effective: Due to their smaller size and efficient design, compact batching plants generally have lower initial costs and reduced operational expenses compared to larger plants.

- High Efficiency: Despite their smaller size, these plants can produce high-quality concrete efficiently, ensuring consistent mix quality and meeting project specifications.

- Reduced Labour Costs: Automation and streamlined processes in compact batching plants minimize the need for manual labor, leading to cost savings.

- Enhanced Control: Advanced control systems in these plants allow for precise measurement and mixing of materials, ensuring consistent concrete quality and reducing waste.

Technical Information

| MODEL | GCP-24 | GCP-30 | GCP-45 | GCP-60 | GCP-75 | GCP-90 |

|---|---|---|---|---|---|---|

| Concrete output capacity (m3/hr) | 24 | 30 | 45 | 60 | 75 | 90 |

| Mixer Capacity (Ltrs.) | 400 | 500 | 750 | 1000 | 1500 | 2000 |

| Batch Capacity (m3) | 0.4 | 0.5 | 0.75 | 1 | 1.25 | 2 |

| Type of Mixer | Pan | Pan / Twin Shaft / Planetary | Twin Shaft / Planetary | |||

| No. of Bins (cross bin) | 4 Nos. | |||||

| Weighing System | Aggregate, Cement, Water, Additive | |||||

| Air Compressor | Yes | |||||

| Discharge Height | 3.8 Mtrs | |||||

Per GAJJAR’s policy of constant upgradation of products, specifications are subject to change without prior notice.

- FAQ?

FAQs About Our Compact Concrete Batching Plant?

A compact concrete batching plant is a space-efficient and portable batching solution designed for smaller construction projects or sites with limited space. It combines all the essential components of a standard batching plant in a compact footprint.

These plants are ideal for:

- Small-scale construction projects.

- Residential and commercial buildings.

- Urban construction in space-constrained areas.

- Road and bridge repairs.

Our compact plants use high-performance mixers, such as twin-shaft or planetary mixers, to ensure consistent and thorough mixing of concrete.

Yes, the control panel features a user-friendly interface with options for automation. It allows operators to manage batching, mixing, and material proportioning with ease.