Planetary Mixer

Gajjar Equipments Pvt. Ltd. is a well-known manufacturer, supplier, and exporter of Planetary Mixers. We design our products keeping the requirements of clients in consideration. Our product is ideal construction equipment for manufacturing asphalt for building roads through batch mixing.

Home » Concrete Mixing Plant » Concrete Mixers » Planetary Mixer

- Our Products

Planetary Mixer

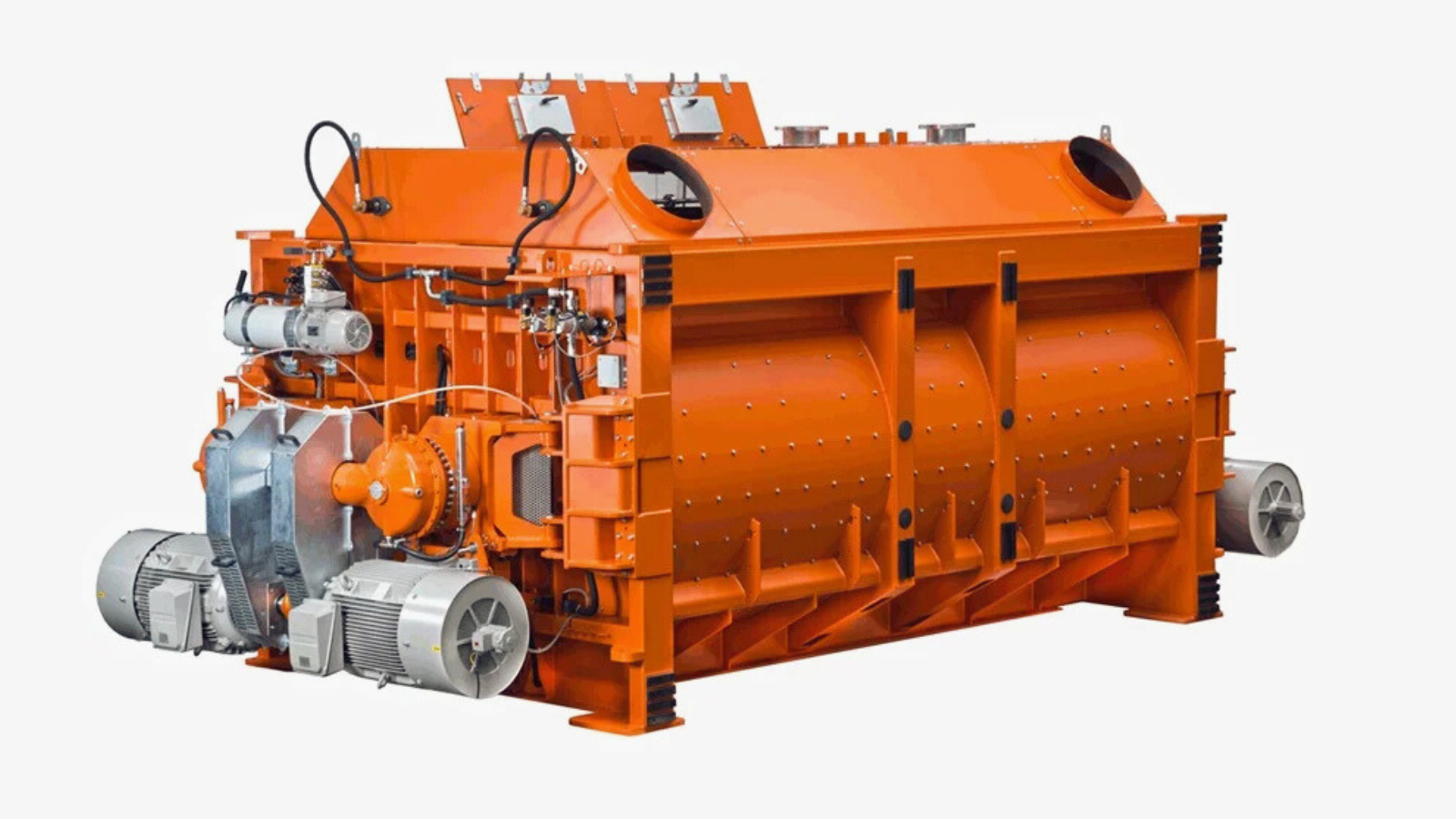

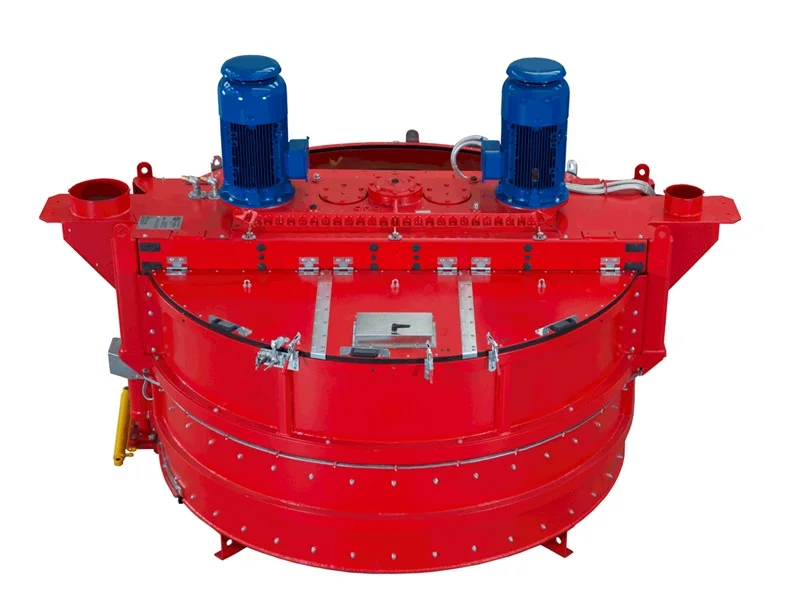

CONCRETE BATCHING PLANETARY MIXER

Gajjar Make Planetary Mixer is engineered to deliver exceptional mixing performance, ensuring the production of high-quality concrete for a variety of construction applications. This mixer is particularly well-suited for projects that demand precise and consistent mixing. Gajjar Make Planetary Mixer is an essential tool for any construction project, providing reliable performance and high-quality concrete production. Whether you are working on a small-scale project or a large construction site, this mixer is designed to meet your needs and exceed your expectations.

HIGHLIGHTS

- Compulsory mixing action gives better strength to concrete.

- Triple armed stars give faster more through mixing action.

- Large pan volume mixer small to full capacity loads with equally fast mixing and discharge times. More Production per hour.

- Anti-wear liner tiles are harder and giving much longer life. More years of production.

- Hydraulically operated rubber Sealed discharge door eliminate leakage, close reliably every time. Manual lever backup.

Exceptional Concrete Mix Output

Capacity Range:

0.5 m3 TO 4.0 m3

Key Features

- Advanced Mixing Technology: The planetary mixing action involves the simultaneous rotation of the mixing blades around their axes and the central axis of the mixer. This dual rotation ensures thorough and uniform mixing of all concrete components, resulting in a consistent and high-quality mix.

- Robust Construction: Constructed with high-grade materials, the mixer is designed to endure the rigors of continuous use in demanding construction environments. The durable build ensures long-term reliability and minimal maintenance.

- Versatile Applications: The mixer is suitable for a wide range of concrete batching applications, including precast concrete, high-performance concrete, and special concrete mixes. It is ideal for both small-scale projects and large construction sites.

- User-Friendly Design: The mixer features an intuitive control panel that allows for easy operation and monitoring of the mixing process. The design also facilitates easy cleaning and maintenance, reducing downtime and enhancing productivity.

- Customizable Options: Available in various capacities and configurations, the mixer can be tailored to meet specific project requirements. Options include different sizes of mixing blades, variable speed settings, and additional accessories for enhanced functionality.

Mixing Blades

Complete the mixing action and give fast discharge. Cast from Ni-hard iron, 550 HB minimum, for extreme wear resistance. Outer edges are thickened to equalize wear and the angle of attack is optimized to push, not slice, to maximize both mixing and blade life.

Mixing Arms

The mixing action starts with the arms, which are responsible for most of the mixing, from top to bottom. Three cast iron arms per star, two stars starting from MP 1875/1250 and three stars for MP 4500/3000 and MP6000/4000. Together with two hardened steel scraping arms they are the best for toughness plus abrasion resistance. Adjustment slots allow easy blade adjustment to compensate for wear.

Hydraulic Power Pack

It has plenty of capacity to operate doors reliably in even the largest mixer. A manual lever allows the door dual use, to be opened during power loss, and to be closed right after.

Technical Information

| MODEL | GPLM-05 | GPLM-10 | GPLM-15 | GPLM-20 | GPLM-25 | GPLM-30 | GPLM-40 | |

|---|---|---|---|---|---|---|---|---|

| CONCRETE OUTPUT PER CYCLE (VIBRATED) | M3 | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 |

| DRY FILLING CAPACITY | M3 | 0.75 | 1.5 | 2.25 | 3 | 3.75 | 4.5 | 6 |

| MAXIMUM LOAD CAPACITY | Kg. | 1200 | 2400 | 3600 | 4800 | 6000 | 7200 | 9600 |

| MIXING MOTOR | kW / HP | 18.5 / 25 | 55 / 75 | 2x30 / 40 | 2x45 / 60 | 2x55 / 75 | 3x45 / 60 | 3x55 / 75 |

| MIXING ARMS / BLADES | Nos. | 3 | 3 | 6 | 6 | 6 | 9 | 9 |

| HYDRAULIC POWER PACK MOTOR | kW / HP | 1.5 / 2 | 4 / 5.5 | 4 / 5.5 | 5.5 / 7.5 | 5.5 / 7.5 | 7.5 / 10 | 7.5 / 10 |

Per GAJJAR’s policy of constant upgradation of products, specifications are subject to change without prior notice.

- FAQ?

FAQs About Our Planetary Mixer?

A Planetary Mixer is a mixing machine designed for thorough and homogenous mixing of materials. It uses a unique planetary motion, where the mixing tools rotate on their axes while also revolving around the mixing bowl, ensuring uniform mixing of materials.

- Uniform and efficient mixing with planetary motion.

- High-quality mixing blades and wear-resistant liners.

- Durable construction for long-term use.

- Easy discharge and cleaning systems.

- Compatibility with automation and control systems.

Our Planetary Mixers are ideal for:

- High-performance concrete (precast, SCC, ultra-high performance).

- Mortars and grouts.

- Mixing pigments, chemicals, and refractory materials.

- Glass, ceramics, and other specialty materials.

The mixer uses a combination of rotation and revolution, where the blades rotate around their own axis and simultaneously revolve around the mixing pan. This motion ensures every part of the material is mixed uniformly.