PAN Mixer

Gajjar Equipments Pvt. Ltd. is a well-known manufacturer, supplier, and exporter of PAN Mixers. We design our products keeping the requirements of clients in consideration. Our product is ideal construction equipment for manufacturing asphalt for building roads through batch mixing.

Home » Concrete Mixing Plant » Concrete Mixers » PAN Mixer

- Our Products

PAN Mixer

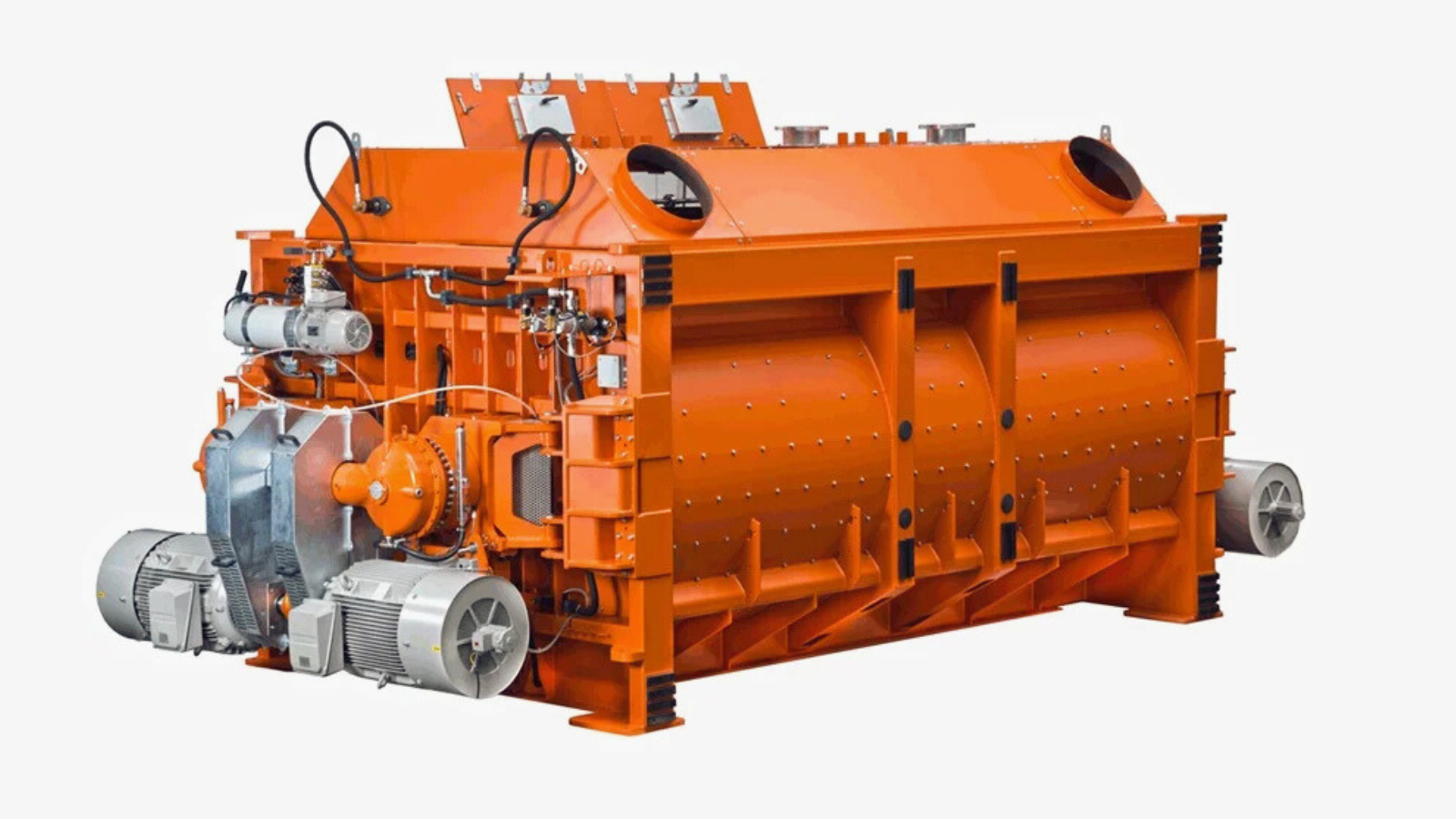

CONCRETE BATCHING PAN MIXER

Gajjar Make Concrete Batching Pan Mixer is designed for efficient and consistent mixing of concrete. This robust and reliable mixer is ideal for a variety of construction projects, ensuring high-quality concrete production.

HIGHLIGHTS

- Newly designed Pan Mixer with outer and inner scrappers for perfect mixing

- The floor & full wall of the mixers are lined with special wear resistant and replaceable plates

- Long service life and low operating cost

- Detachable arms & easy fittings

- Easy for maintenance

- Rubber lined arms

Exceptional Concrete Mix Output

Capacity Range:

0.5 m3 TO 3.5 m3

Key Features

- High Mixing Efficiency: The pan mixer design ensures thorough and uniform mixing of all concrete components, resulting in a consistent mix every time.

- Durable Construction: Built with high-quality materials, the mixer is designed to withstand the rigors of continuous use in demanding construction environments.

- Easy Operation and Maintenance:The user-friendly design allows for easy operation and maintenance, minimizing downtime and maximizing productivity.

- Versatile Applications: Suitable for a wide range of concrete batching applications, from small-scale projects to large construction sites.

- Customizable Options: Available in various capacities and configurations to meet specific project requirements.

Mixing Arms

All the mixing arms are connected to the rotating drive system with spring shock absorbers operated by cams. This system absorbs any shock loads caused by the mix blades hitting obstructions and protects the drive gearbox. It also allows easy adjustment of the mix blades clearance to the tank floor.

Discharge Door

All parts of the discharge door/s are produced using very accurate CNC machining and the full door assembly is then bolted to the tank. This guarantees the correct positioning of the door and that the door segment rotates in a perfect arc and is in contact with the rubber door seal on the tank. This prevents any unwanted leakage when the door is closed and prevents any possibility of the door jamming.

Technical Information

| MODEL | GPLM-05 | GPLM-10 | GPLM-15 | GPLM-20 | GPLM-25 | GPLM-30 | GPLM-40 | |

|---|---|---|---|---|---|---|---|---|

| CONCRETE OUTPUT PER CYCLE (VIBRATED) | M3 | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 |

| DRY FILLING CAPACITY | M3 | 0.75 | 1.5 | 2.25 | 3 | 3.75 | 4.5 | 6 |

| MAXIMUM LOAD CAPACITY | Kg. | 1200 | 2400 | 3600 | 4800 | 6000 | 7200 | 9600 |

| MIXING MOTOR | kW / HP | 18.5 / 25 | 55 / 75 | 2x30 / 40 | 2x45 / 60 | 2x55 / 75 | 3x45 / 60 | 3x55 / 75 |

| MIXING ARMS / BLADES | Nos. | 3 | 3 | 6 | 6 | 6 | 9 | 9 |

| HYDRAULIC POWER PACK MOTOR | kW / HP | 1.5 / 2 | 4 / 5.5 | 4 / 5.5 | 5.5 / 7.5 | 5.5 / 7.5 | 7.5 / 10 | 7.5 / 10 |

- FAQ?

FAQs About Our PAN Mixer?

A PAN Mixer is a machine used to mix various materials like concrete, mortar, or other mixtures. It features a round mixing pan where the materials are thoroughly mixed by rotating blades or paddles.

- Durable steel construction.

- High-efficiency mixing blades.

- Easy loading and unloading process.

- Optional customizations for size and capacity.

- Easy to clean and maintain.

Our PAN Mixers are suitable for mixing concrete, refractory materials, chemicals, pigments, and other granular or powdered substances.

Yes, the mixer is designed with user-friendly controls for ease of operation. It also includes safety features to ensure secure usage.