Precast Concrete Plant

Gajjar Equipments Pvt. Ltd. is a well-known manufacturer, supplier, and exporter of Precast Concrete Plants. We design our products keeping the requirements of clients in consideration. Our product is ideal construction equipment for manufacturing asphalt for building roads through batch mixing.

Home » Concrete Mixing Plant » Ready Mix Concrete Plants » Precast Concrete Plant

- STATIONARY

Precast Concrete Plant

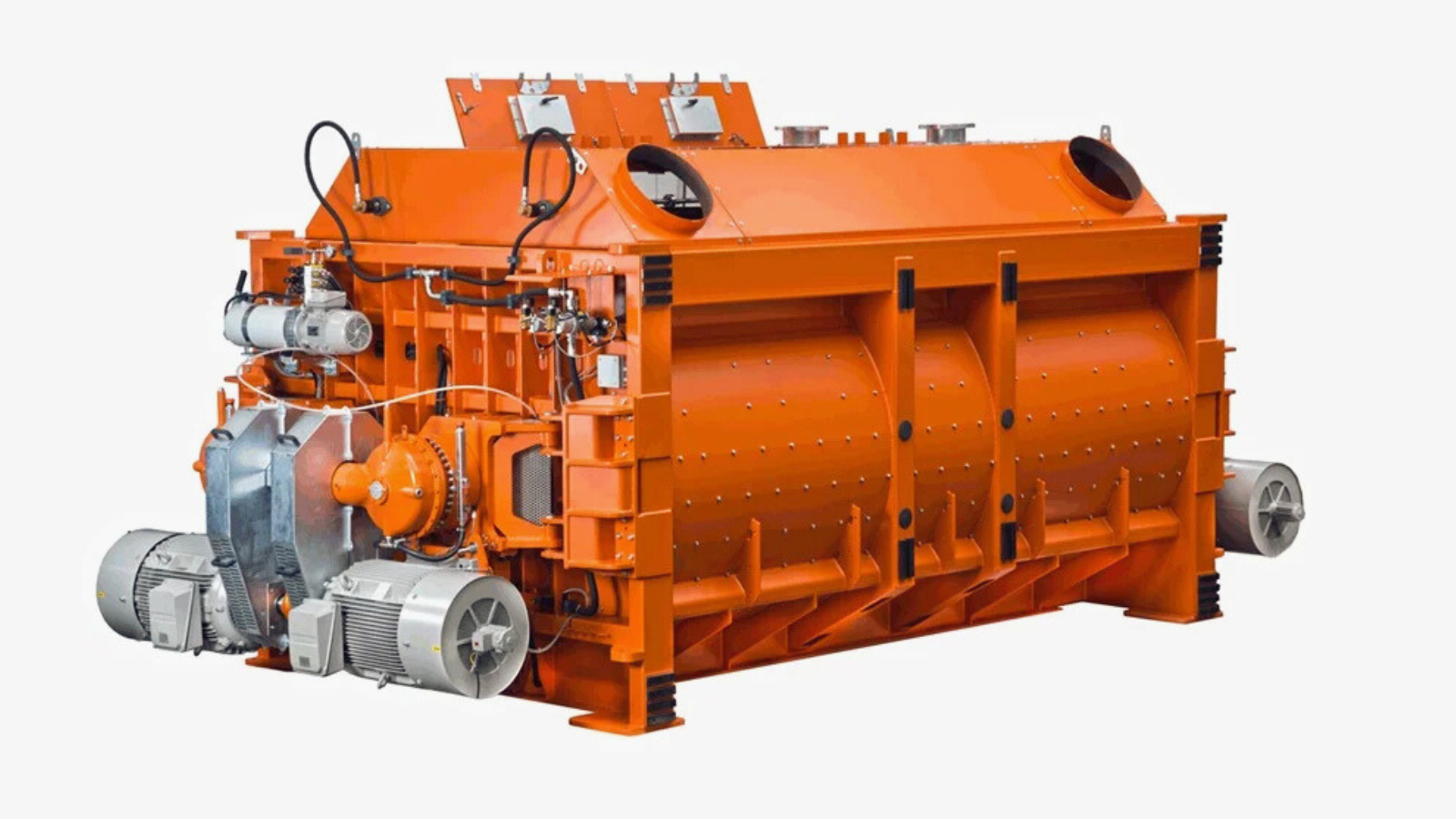

GAJJAR stationary plants for precast applications are being designed individually according to the machines, site conditions, buildings, and required production capacities. With maximum efficiency and reliability for producing all types of high quality, colored, and low slump mixes. GAJJAR offers mixer capacities from 0.25 m³ up to 2.0 m³ per batch. Precast plants are available with a variety of options and can be configured to meet each client’s individual needs.

GAJJAR precast concrete plant is designed for the efficient production of high-quality precast concrete elements. The plant features advanced batching systems that ensure precise measurement and mixing of raw materials like cement, aggregates, water, and admixtures. Reusable molds are prepared and filled with the homogenous concrete mix, followed by controlled curing in specialized chambers to achieve optimal strength and durability. The plant includes state-of-the-art handling equipment for the safe and efficient transportation of precast elements. Rigorous quality control measures are implemented at every stage to ensure the final products meet stringent standards.

Exceptional Concrete Mix Output

Capacity Range:

60 M3 TO 240 M3

HIGHLIGHTS

- Produces high-quality, durable concrete elements with consistent properties

- Batching systems that precisely measure and mix raw materials

- Reusable molds and forms can be customized for specific projects or standardized for common components

- Customizable solutions to meet the specific needs of different projects

- Comprehensive support, including installation, training, and maintenance services, ensuring smooth operation

Advantages of Counterflow Drum Mix Plant

- Building Construction: Precast concrete is commonly used for beams, columns, floor slabs, wall panels, and other structural components in residential, commercial, and industrial buildings.

- Reduced Emissions: The efficient dust collection system minimizes the release of pollutants.

- Architectural Elements: Precast concrete can be used to create decorative facades, cladding panels, and other architectural features that enhance the aesthetic appeal of buildings

- Utility Structures: Precast concrete is used for utility structures such as manholes, utility vaults, and drainage systems.

Working Principle

1. Material Preparation and Batching

In a precast concrete plant, raw materials like cement, aggregates, water, and admixtures are stored in silos and bins. These materials are precisely measured and weighed using automated systems to ensure consistent quality. The measured materials are then mixed in high-performance mixers to create a homogenous concrete mix. Moisture sensors and regular testing ensure the mix meets the required standards. This process ensures the production of high-quality, durable precast concrete elements.

2. Molding and Pouring

In a precast concrete plant, reusable molds are cleaned and prepared for concrete pouring. The mixed concrete is then poured into these molds, ensuring even distribution with the help of vibrators to remove air bubbles. The concrete is allowed to set initially in the molds. Once set, the molds are transferred to curing chambers for controlled curing. This process ensures the concrete achieves the desired strength and quality.

3. Curing

In a precast concrete plant, curing involves transferring the molds with freshly poured concrete to controlled curing chambers. These chambers maintain specific temperature and humidity levels to accelerate the curing process. This controlled environment ensures the concrete achieves the desired strength and durability. Proper curing is essential for producing high-quality precast elements.

4. Demolding and Finishing

Once the concrete has reached the desired strength, the precast elements are carefully removed from the molds. Each element is inspected for quality and any defects are addressed. The surfaces may undergo treatments like polishing or painting to achieve the desired finish. Additional reinforcement may be added if required, ensuring the elements meet all specifications.

Planetary Mixer

GAJJAR makes precast concrete plants are equipped with planetary mixers. Planetary mixers provide thorough and uniform mixing of concrete, ensuring that all particles are evenly distributed. This is crucial for achieving consistent quality in precast elements. These mixers can handle a wide range of concrete types, including high-performance and self-compacting concrete, making them suitable for various precast applications. Planetary mixers operate at high speeds, reducing the mixing time and increasing overall productivity. This is beneficial for large-scale production. Built with robust materials and abrasion-resistant linings, planetary mixers are designed to withstand the rigors of continuous use, ensuring long-term reliability.

Technical Information

| MIXER CAPACITY (m3/batch) | 0.25 | 0.375 | 0.5 | 0.75 | 1 | 1.5 | 2 |

|---|---|---|---|---|---|---|---|

| Aggregate Storage System | Inline bin / compartment | Inline bin / compartment | Inline bin / compartment | Inline | Inline | Inline | Inline |

| Bin Capacity (m3 / each bin) | 5 | 5 | 7.5 | 10 | 15 | 20 | 25 |

| Type of Mixer | Planetary Mixer | ||||||

| Aggregate Weighing System | Weighing Bin With Belt Conveyor | ||||||

| Aggregate Loading in Mixar | Belt | ||||||

| Control System | FULLY AUTOMATIC PLC | ||||||

Per GAJJAR’s policy of constant upgradation of products, specifications are subject to change without prior notice.

- FAQ?

FAQs About Our Precast Concrete Plant?

A precast concrete plant is a facility designed to produce precast concrete elements, such as beams, slabs, columns, panels, and more, in a controlled environment. These elements are then transported to the construction site for assembly.

Our plants can produce a wide variety of precast elements, including:

- Walls and partitions.

- Floor and roof slabs.

- Beams and columns.

- Pipes and culverts.

- Staircases and retaining walls.

Quality Control: Manufacturing in a controlled environment ensures superior quality.

Efficiency: Speeds up construction timelines by producing ready-to-install components.

Durability: Precast elements are highly durable and weather-resistant.

Cost-Effective: Reduces labor costs and material wastage.

Our precast concrete plants come in varying capacities, from 60 m³ to 260 m³, depending on project requirements.